Vibrating Motor

Vibrating Motor

So-called vibrated mechanism refers to those to have been equipped with the vibrating motors.

When the motor is actuated to produce vibration which would be in consonance with mechanism action, so to in turn push the carried objects moving toward designed direction at designed angle.

| Precautions in installment and adjustment | ||

|---|---|---|

| 1. | Before and after adjusting the vibrating force, it is necessary to secure the adjusting screw in order to prevent the vibrating vanes from jumping out. | |

| 2. | Constantly check the securing screw on foot and the outlet cord for sure security and normal operation. | |

| 3. | in selection of motor base, the tensile strength of the base should be taken into consideration so that the mechanism may not be damaged. | |

| 4. | Under the normal usage, the maintenance practice should be conducted once every 3000hours of running. | |

| Primary structure | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1. Coil and isolation processing: | The motor coil is made of the wire coated with H type isolating paint and received adequate vibrating-proof processing. | ||||||||||

| 2. Rotating shaft: | which is made of the rigid chrome steel which is facilitative to the load of vibrating vane centrifugal force. | ||||||||||

| 3. Bearing: | This motor is designed and manufactured for the industrial circle in which the vibrating device is mandatory in their production facility, so it must be stable and heavy-duty in structure; however, its consuming spare parts are still in need of regular care or maintenance with a view to extending its service life. All the ball-shape bearings used in this motor have their longer service life records. Additionally, they are easy to replace. | ||||||||||

| 4. Derivative vibrating vanes: | They are made of top line quality case iron. In setting up operation, it must be adjusted to produce adequate vibrating force and then to have it fixed at both ends. | ||||||||||

| 5. Outlet cord: | The extension cord at outlet is subject to damage due to vibrating, so it is double protected by metal and rubber sleeves. | ||||||||||

| 6. The beads service life: | As the service life of SKF steel beads is various with types; all of them are marked with the service life more than 3000hours, that is certainly staggering. | ||||||||||

| 7. This motor can run long time. | |||||||||||

| 8. In case, customers want their motors to be water-proof, and explosion-proof or to be made in accordance with their own specification, a specific order can be placed to meet the requirement. | |||||||||||

| Usage | ||

|---|---|---|

| Its application is versatile, such as banking / pouring compaction, out-flowing selection, and shipping./ handling operations in industrial field. | ||

| 1. Banking/ pouring/ filling: | Used in civil engineering, by battery factory, metal plumber manufacturers, or sand filling/ compaction operation etc. | |

| 2. Compaction: | Used on vibrating rollers, or cement compaction | |

| 3. Outflow: | Used on hoppers in industrial field | |

| 4. Selection: | For Screening Material Size | |

| 5. Vibrating stand: | Used on various vibrating stand to remove to casting sand | |

| 6. Shipping/ Handling: | Used to drive the conveying belt | |

| 7. Drying transfer purpose. | ||

2poles

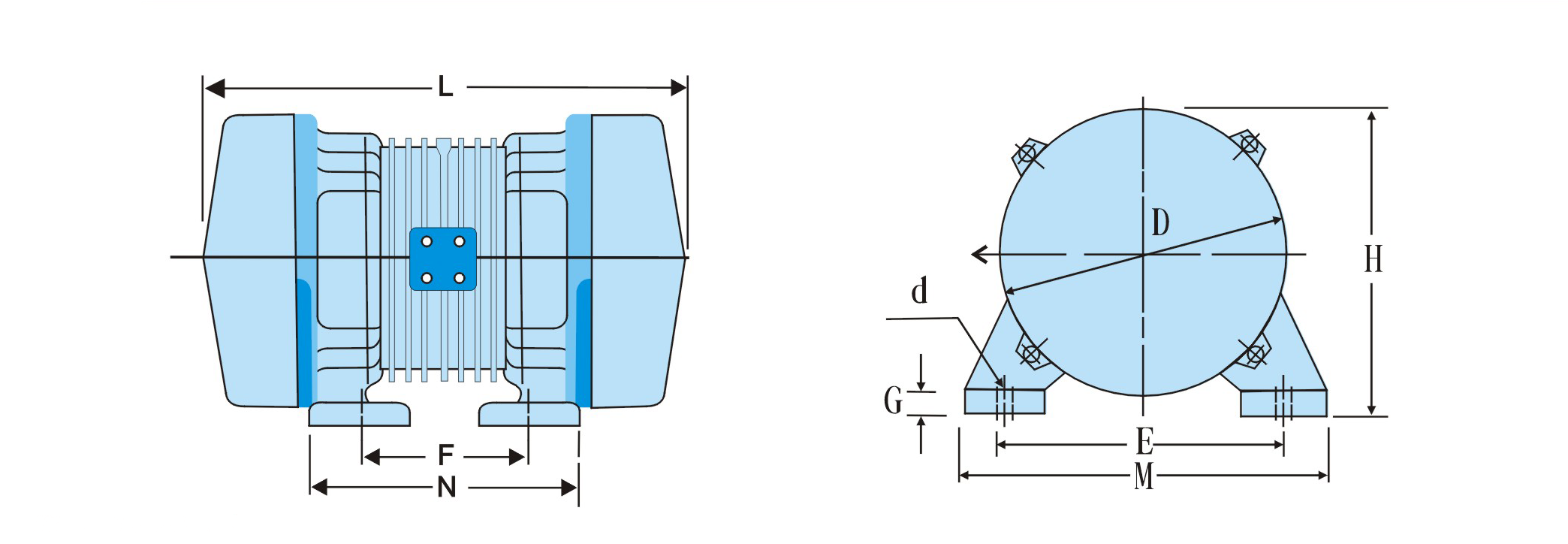

| SIZE TYPE | Vibration | Output | Voltage | Vibrations | D | E | F | G | H | L | M | N | D | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| energy(kg) | KW | HP | (V) | per min | ||||||||||

| 2P-10 | 75 | 0.075 | 1/10 | 380 | 2850 | 103 | 115 | 40 | 15 | 110 | 210 | 150 | 73 | 11 |

| 2P-11 | 150 | 0.1 | 1/8 | 380 | 2850 | 113 | 120 | 140 | 15 | 144 | 255 | 155 | 175 | 14 |

| 2P-15 | 350 | 0.25 | 1/3 | 380 | 2850 | 150 | 150 | 106 | 15 | 155 | 255 | 190 | 158 | 15 |

| 2P-18 | 600 | 0.4 | 1/2 | 380 | 2850 | 180 | 180 | 102 | 16 | 187 | 305 | 227 | 173 | 19 |

| 2P-21 | 1000 | 0.75 | 1 | 380 | 2850 | 210 | 210 | 120 | 21 | 220 | 340 | 260 | 200 | 20 |

4poles

| SIZE TYPE | Vibration | Output | Voltage | Vibrations | D | E | F | G | H | L | M | N | D | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| energy(kg) | KW | HP | (V) | per min | ||||||||||

| 4P-11 | 100 | 0.1 | 1/8 | 380 | 1420 | 113 | 120 | 140 | 15 | 144 | 255 | 155 | 175 | 14 |

| 4P-15 | 250 | 0.125 | 1/6 | 380 | 1420 | 150 | 150 | 106 | 15 | 155 | 254 | 190 | 158 | 15 |

| 4P-18 | 500 | 0.2 | 1/4 | 380 | 1420 | 180 | 180 | 102 | 16 | 187 | 305 | 277 | 173 | 19 |

| 4P-21 | 800 | 0.4 | 1/2 | 380 | 1420 | 210 | 210 | 120 | 21 | 220 | 340 | 260 | 200 | 20 |

| 4P-24 | 1600 | 0.75 | 1 | 380 | 1420 | 240 | 260 | 143 | 27 | 265 | 385 | 324 | 237 | 25 |

| 4P-28 | 2400 | 1.12 | 11/2 | 380 | 1420 | 275 | 260 | 150 | 35 | 285 | 420 | 325 | 240 | 25 |

| 4P-31 | 3200 | 1.5 | 2 | 380 | 1420 | 310 | 310 | 190 | 40 | 330 | 545 | 395 | 318 | 29 |

| 4P-35 | 5000 | 2.2 | 3 | 380 | 1420 | 350 | 380 | 240 | 50 | 365 | 600 | 480 | 395 | 32 |

| 4P-40 | 7500 | 3.7 | 5 | 380 | 1420 | 400 | 380 | 290 | 58 | 450 | 785 | 500 | 468 | 41 |

6poles

| SIZE TYPE | Vibration | Output | Voltage | Vibrations | D | E | F | G | H | L | M | N | D | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| energy(kg) | KW | HP | (V) | per min | ||||||||||

| 6P-21 | 400 | 0.25 | 1/3 | 380 | 1000 | 210 | 210 | 120 | 21 | 220 | 340 | 260 | 200 | 20 |

| 6P-24 | 800 | 0.4 | 1/2 | 380 | 1000 | 240 | 260 | 143 | 27 | 265 | 385 | 324 | 237 | 25 |

| 6P-28 | 1600 | 0.75 | 1 | 380 | 1000 | 275 | 260 | 150 | 35 | 285 | 420 | 325 | 240 | 25 |

| 6P-31 | 2400 | 1.5 | 2 | 380 | 1000 | 310 | 310 | 190 | 45 | 330 | 545 | 395 | 330 | 29 |

| 6P-35 | 4000 | 2.2 | 3 | 380 | 1000 | 350 | 380 | 240 | 50 | 365 | 600 | 480 | 395 | 32 |

| 6P-40 | 5800 | 3.7 | 5 | 380 | 1000 | 400 | 380 | 290 | 58 | 450 | 785 | 500 | 468 | 41 |

8poles

| SIZE TYPE | Vibration | Output | Voltage | Vibrations | D | E | F | G | H | L | M | N | D | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| energy(kg) | KW | HP | (V) | per min | ||||||||||

| 8P-24 | 500 | 0.4 | 1/2 | 380 | 720 | 240 | 260 | 143 | 27 | 265 | 385 | 324 | 237 | 25 |

| 8P-31 | 1000 | 0.75 | 1 | 380 | 720 | 310 | 310 | 190 | 40 | 330 | 545 | 395 | 318 | 29 |

| 8P-35 | 2000 | 1.5 | 2 | 380 | 720 | 350 | 380 | 240 | 50 | 365 | 600 | 480 | 395 | 32 |

| 8P-40 | 3000 | 2.2 | 3 | 380 | 720 | 400 | 380 | 290 | 58 | 450 | 785 | 500 | 468 | 41 |